In 1987, the federal government began phasing in its ban on toxic lead shot for waterfowl hunting. The ban spread nationwide in 1991. Waterfowlers scrambled to find alternatives to lead. Even pheasant hunters had to find nontoxic options if they hunted federal waterfowl production areas and national wildlife refuges.

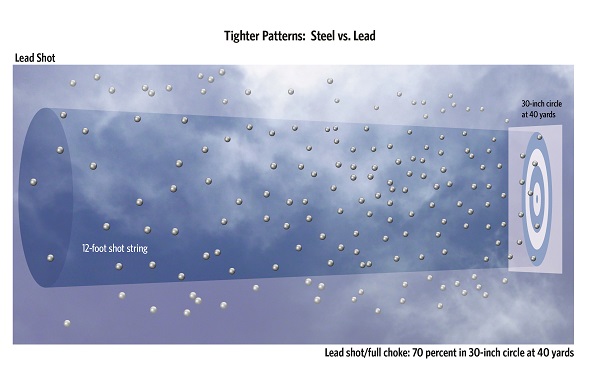

The alternatives—mostly steel shot—weren’t good. Caught unprepared by the ban, ammo makers basically just switched steel shot for lead. The lighter-weight steel pellets had less velocity and energy at target distances. Steel patterned more tightly, shrinking the “kill zone.” Hunters crippled more birds. Steel shot immediately got a bad reputation.

But in the quarter century since the ban, manufacturers have greatly improved steel. In fact, steel has gotten so good that many pheasant hunters shoot it all the time. Some hunters want to hunt lead and no-lead zones without having to empty their pockets and change shells. Others like using the same loads for all of their hunting to improve shooting consistency. And others make a personal choice to shoot non-toxic shot, so they hunt with steel even when they could shoot lead instead.

Says Erik Carlson, manager of engineering for

Federal Cartridge, “There are some pretty affordable, good options out there with steel.”

The Evolution of Steel

Before the ban, there was no reason for steel shot. Lead was malleable, soft on barrels and chokes, easy to manufacture, cheap, and dense. Says Carlson, “From the beginning of when people started using guns, lead was a part of the product.”

With the ban, ammo manufacturers tried materials such as bismuth and tungsten, which were dense like lead. But they were also expensive.

Most shot shell makers concentrated on steel. Steel was nearly as cheap as lead. But it had two big disadvantages.

First, it was rock hard. It didn’t compress like a load of lead shot as it traveled down the barrel, so it could damage full-choke guns that weren’t designed for it (and before 1987, of course, none were). And because it didn’t deform, it didn’t respond well to chokes. (The hardness did provide one advantage: The shot stayed round and flew true, with fewer “flyers.”)

But steel’s biggest drawback—its low density, just 7.8 grams per cubic centimeter compared with lead’s 11.34. “You can get the freight train of lead moving and it tends to hold its energy farther out than steel would,” says Carlson. Steel loads, on the other hand, “slow down fast because they are like throwing a whiffle ball versus a baseball.” As steel loses speed, it also loses energy, penetration, and lethality.

Steel with Speed and Power

The solution seemed obvious: Jack up velocity so that the steel shot would match the velocity and energy of lead at 40 yards. Higher speed and less time to the target would also reduce drift of the lightweight steel pellets in a crosswind.

“There were two ways to go about it,” says Carlson. “It was make the steel go really fast. The other one was try to make shot similar to lead’s density. So bismuth and tungsten and all these started showing up on the market.” But bismuth and tungsten were expensive. So most manufacturers focused on steel.

But here’s the rub: An ounce of steel takes up a lot more room than an ounce of lead. It’s tough to cram a suitable payload of steel into a 2-3/4-inch—or even a 3-inch—shell and have enough room for the powder necessary to boost the speed of the load.

Shot shell engineers found space by reducing the size of the so-called hinged wad. The cushy wad acted both to reduce felt recoil and, more importantly, to reduce the pressure of the load. Trimming down the wads while loading more powder created dangerously high chamber pressures.

Higher-speed steel shot created another problem: blown patterns. With conventional wads, pattern density decreased as velocity increased.

So, to boost speed and create a load that could compete with traditional lead, engineers had to improve several features more or less at once.

Powder and primers. Powders had to burn slower to reduce the initial chamber pressure but to continue to accelerate the payload down the barrel. New powders burned cleaner and slower, keeping pressures down. New primers helped reduce chamber pressures on ignition.

Wads. Early wads and shot cups sprung open the instant they left the barrel. To contain shot and create more consistent patterns at higher speeds, manufacturers designed wads to hold shot together until it is travels well beyond the muzzle.

Shot design. Most steel shot is spherical. But some manufacturers have fiddled with shot shape to increase killing power and to emulate the drift characteristics of lead pellets, some of which deform on their way down the barrel.

The result of these innovations—steel shot loads that perform virtually as well as lead. Ammo manufactures tweaked their designs in different ways. A good example of an effective modern steel load is

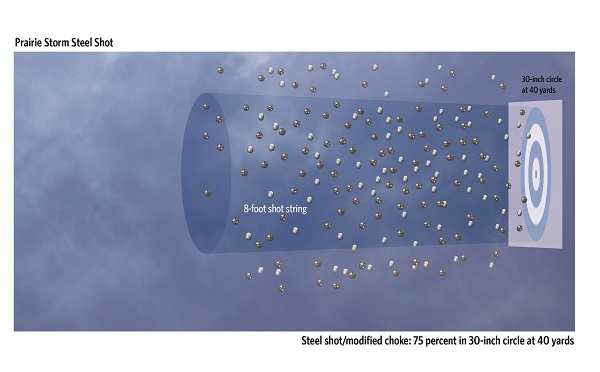

Federal’s Prairie Storm Steel, which comes in 3-inch shells pushing number 3 or 4 steel shot at 1,600 feet per second in 12-gauge and 1,500 fps in 20. That compares with about 1,200 fps for an old-fashioned lead load.

.jpg.aspx)

What they wanted us to do in the Prairie Storm Steel is to create a 12-gauge upland steel load that has the same pellet count and the same 40-yard velocity as an 1-1/4-ounce number 4 lead,” says Erik Carlson. For example, a 1-1/4 ounce of number 4 lead has 169 pellets. Number 3 steel at 1-1/8 ounces has 178 pellets. “What you really care about is how many pellets are getting out there and what’s their energy when they hit the target,” says Carlson. “We found that if we sped it up to 1600 feet per second, which is fast, we could give them that 40-yard performance that we see with lead.”

In Prairie Storm, Federal mixes 50 percent standard spherical steel with 50 percent Flitestopper pellets, which have sharp belts like cartoon flying saucers. The odd shapes cause the pattern to open a bit and get good distribution on the target, Carlson says. “Because of that band they naturally want to drift away from the center of the target.”

The band also tears flesh on impact, transferring all its energy to the bird and increasing killing power, Carlson says. “When we shoot gelatin, we always see the Flitestopper not penetrate as far [as spherical shot]. It’s transferring energy quicker to the target. It’s still deep enough. We found that the cutting edge gave us the lethality we were looking for.”

Flanges on the rear of the Flitecontrol wad open on leaving the muzzle. Says Carlson, “The wad pulls itself away and you get very consistent patterns.”

Federal Ammo’s Black Cloud is marketed to waterfowlers, with identical shot and wad, at somewhat different velocities, shot sizes, and ratios of spherical and Flitestopper pellets.

Shooting Steel

Regardless of brand, manufacturers agree on a few adjustments to using steel.

- Pick shot one or two sizes larger than lead. If you shoot number 6 lead for pheasants, shoot number 4 in steel.

- Open your choke. Steel shot doesn’t respond to chokes very well. And the Flitecontrol wad makes a full choke unnecessary. Instead, try an improved cylinder or modified choke for best patterns. Depending on the gun, Prairie Storm Steel delivers more than 75 percent of their pellets in a 30-inch circle at 40 yards—denser than the traditional measure of a full choke, which is 70 percent.

- For close range, shoot smaller pellets. Guns pattern less tightly with smaller shot—about 4 percent fewer pellets per shot size smaller, says Federal’s Carlson. “They slow down faster and as they slow down they drift from the target.”

- Adjust your lead. If you’re used to standard lead loads and pick up a box of 1,600-fps steel, you may need to shorten your lead a bit.

- Save steel for shotguns made for it. In a vintage gun, especially a double or a gun with a fixed full choke, try bismuth or tungsten matrix shot, both of which are soft, like lead.

Story by Greg Breining, illustrations by Breeze Communication Arts

Story by Greg Breining, illustrations by Breeze Communication Arts

Main image from ATK